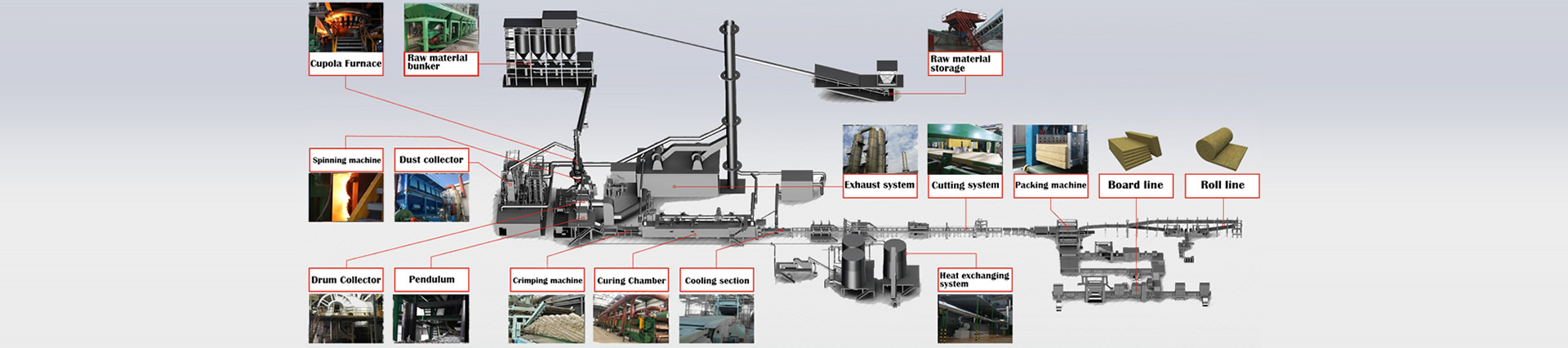

Cupola Furnace

.png)

.jpg)

Made by boiler plate with thickness of 18mm; diameter 1600 mm;

Twenty one combustion tuyeres;

Equipped with raw material dispersing apparatus on the top of feeder nose;

Melting temperature: 1600℃;

Productivity: maximum 6 t/h.

Cupola

(1)Function

Used for raw material melting.

(2)Structure

Cupola is consisted with furnace body with water cooling jacket, furnace bottom door and hydraulic opening device, furnace bottom iron notch and hydraulic opening device, air blowing mouth and vane, siphon mouth, upper furnace body, feeding mouth, hydraulic pressure station, material level meter etc.

The main advantages of the cupola furnace are:

•Possibility of switch off / on in a short time;

•Reduced costs and easy maintenance;

•Ability to recycle waste of the production line turning it into briquettes;

•High operating flexibility.